Biogradex® is an activated sludge (biological) wastewater treatment process utilizing very high mixed liquor suspended solids (MLSS) concentration and low food to microorganism (F:M) ratio. The treatment process is only applicable for biological nutrient removal (BNR), continuous flow type facilities. The technology vastly improves settling of activated sludge, and enhances nitrification and denitrification processes.

The treatment systems are based on well recognized BNR type treatment processes and bioreactor configurations, the only addition being the Biogradex® installation allowing degasification of mixed liquor in vacuum conditions between the bioreactor and secondary clarifiers. As a result of the degasification MLSS concentration can be increased from conventional 3,500-4,500 mg/L to 6,000-9,000 mg/L or even higher (the highest recorded MLSS at one of the existing plants was 12,000 mg/L). The surface solids loading of secondary clarifiers can be increased from conventional 70-100 kg/m2 d to 150-200 kg/m2 d without negative process effects. Without use of degasification such increase in MLSS concentration is impossible due to the solids carry over (“escape”) from secondary clarifiers. Use of degasification allows process to continue at F:M ratio of about 0.05 kg/kg since biomass quantity is practically doubled without increase in volume of the bioreactor.

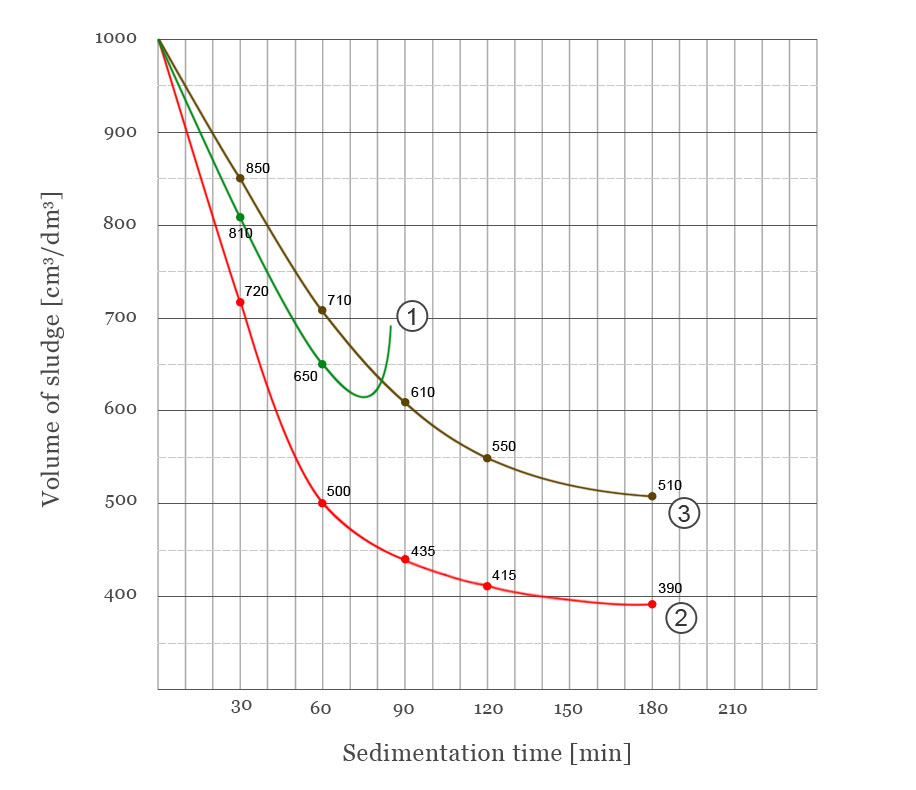

Thanks to the vacuum degasification process floc does not contain any gas in the form of micro bubbles and concentration of gases (especially nitrogen) in water is below saturation levels. Sludge settles very well what is presented on the sedimentation curve below.

Sedimentation Curve

1 – Activated sludge without degasification floats after 75 minutes

2 – Activated sludge after degasification

3 – Returned Activated Sludge (RAS)

The treatment process including vacuum degasification was tested by the Polish Institute of Environmental Protection during 7 days trials. Tests confirmed high efficiency of wastewater treatment process using the Biogradex® technology. In the event of denitrification processes occurring in the secondary clarifier released nitrogen gas dissolves in under saturated condition and does not form micro bubbles which cause floating sludge in secondary clarifiers. Thanks to this it is possible to “store” activated sludge in secondary clarifiers using deep sludge blanket (2-3.5 m deep) without any sludge carry over. This comes especially handy during storm flows. The phenomenon was observed in several of the existing plants.

The influence of vacuum degassing on the activated sludge. Morphology tests confirmed there was no detrimental effects of degassing on the activated sludge floc and floc was very effective in providing process treatment performance. Following is a microscopic image of floc after degassing process.

The simplest process flow diagram (PFD) of treatment process utilizing Biogradex® technology includes:

It doesn’t matter however what existing or planned configuration of BNR treatment process is and shape of bioreactor and secondary clarifier. Biogradex® technology works independently and for every BNR process - as a result of using the technology there is immediate improvement in treatment results which only get better in a few days from technology implementation.

Advantages of using Biogradex® technology for the existing plants:

-

No need for bioreactor volume expansion.

-

Simple maintenance, low energy consumption (0.02 – 0.03 kWh/m3).

-

Full utilization of existing plant infrastructure.

-

Installation of the equipment with minimal interruption to the service.

-

Full design results of vacuum degasification implementation within one week to one month from the time of new treatment system.

-

Simplified documentation and permitting process since process is considered an upgrade only of existing facility.

Advantages of using Biogradex® technology for the new plants:

-

Total plant area required reduces by 25-35 percent in comparison to conventional technologies.

-

Reduced volume and area of bioreactors and secondary clarifiers by 40-50 percent.

-

Higher concentration of air diffusers (2-3 times) creates better oxygen utilization in the treatment process.

-

Energy consumption reduced by 20%.

-

Due to reduced tank surface there are lesser heat losses in winter, higher wastewater temperatures result in better treatment efficiency.

Biogradex® technology presents even more advantages since MLSS concentration can be widely regulated. High concentration of RAS and wasted activated sludge (WAS) creates an advantage for dewatering processes. Partially digested sludge from the system doesn’t really require a separate digestion system (sludge is partially stabilized in the treatment process).

WWTPs using Biogradex® technology are very resistant to water flow fluctuations and changing weather conditions. Wastewater treatment facilities can accommodate storm flows, so there is no need for construction site review and implementation plan.